Aerospace Standards

AS9110 – Quality Management Systems Requirements for Aviation Maintenance Organizations

AS9110 is a standard that defines the quality system requirements for organizations whose primary business is in the aircraft industry at all levels of the MRO (Maintenance, Repair & Overhaul) process. This standard also references several other standards that an organization must understand and integrate into their QMS.

Critical Standards for AS9110 Implementation:

The following pages discuss critical aspects of AS9110. You should be familiar with them, and we recommend buying the standard.

- ARP 9134A – Supply Chain Risk Management. The guideline focuses on Quality as a key risk assessment factor taking into account elements from all aspects of the business having a direct link to global quality management.

- AS5553D – Counterfeit Electronic Parts. This standard is for use by organizations that procure and/or integrate EEE parts and/or assemblies containing such items.

- AS9015A – Work Transfer Supplier Self Verification Process. This standard defines the requirements for a delegation process identified in Aerospace Quality Management System standards.

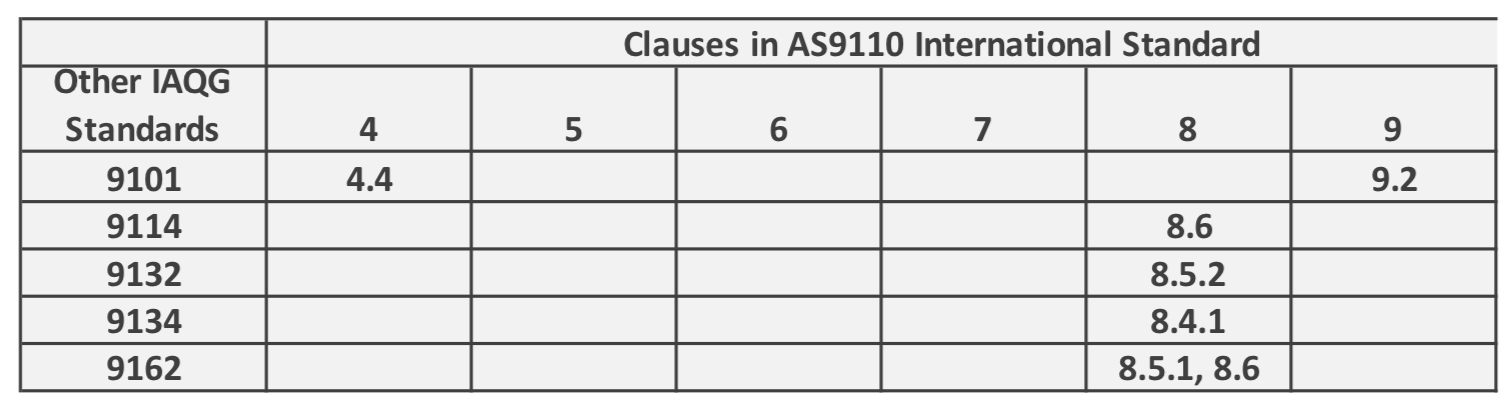

- AS9101 – QMS Audit Requirements. This standard defines requirements for the preparation and execution of the audit process.

- AS9102 – First Article Inspection. This standard establishes the baseline requirements for performing and documenting FAI.

- AS9103A – Key Characteristics. This standard is primarily intended to apply to new parts and products but can also be applied to parts currently in production.

- AS9131D – Nonconformance Documentation. This standard defines the common nonconformance data definition and documentation that must be exchanged between an internal/external supplier or sub-tier supplier, and the customer when informing about a nonconformity requiring formal decision.

- AS9146 – Foreign Object Detection (FOD). This standard defines FOD Prevention Program requirements for organizations that design, develop, and provide aviation, space, and defense products and services. And by organizations providing post-delivery support, including the provision of maintenance, spare parts, or materials for their own products and services.

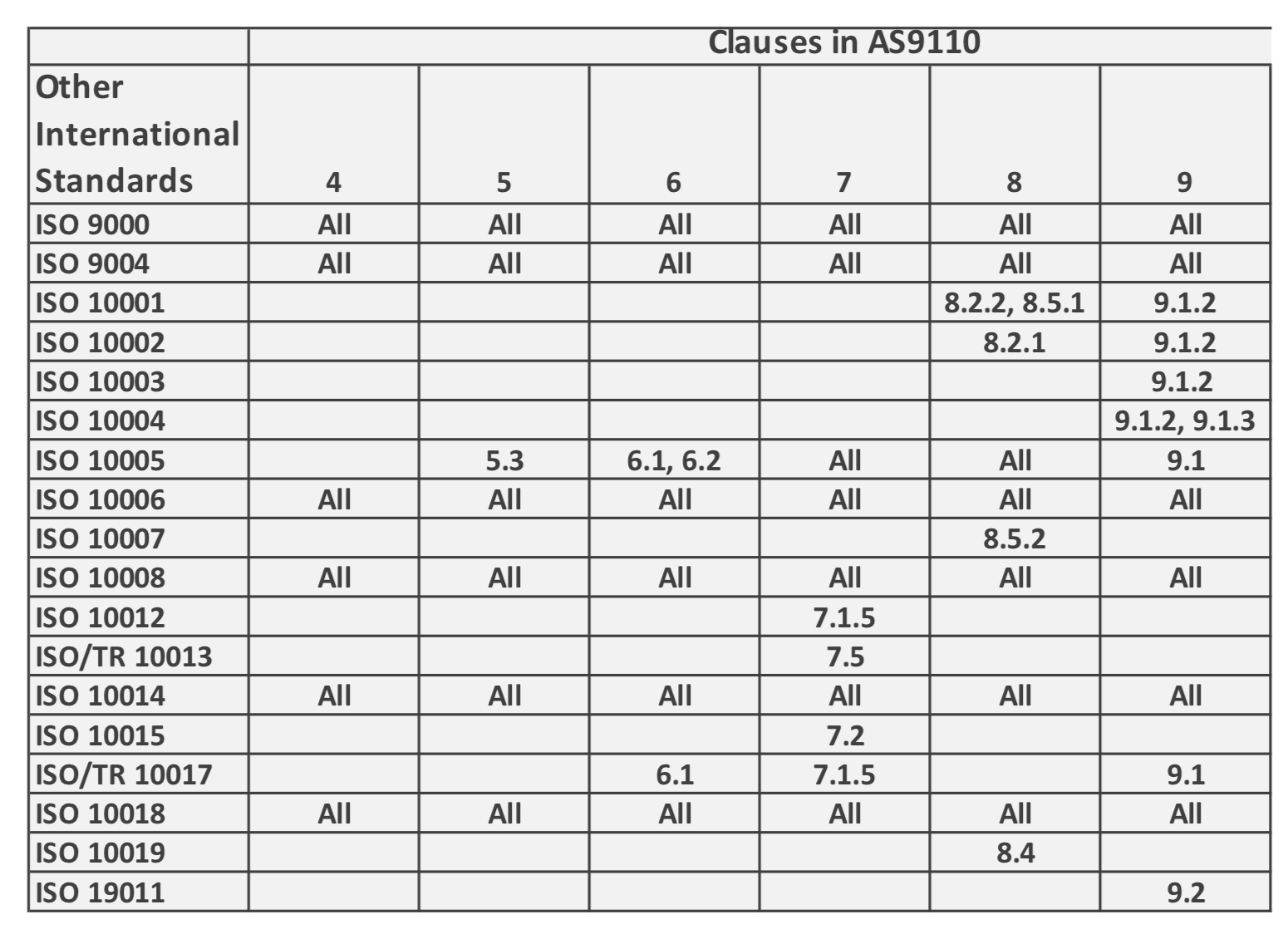

- ISO 10006 – Project Management. This standard gives guidelines for the application of quality management in projects.

- ISO 10007 – Configuration Management. This standard provides guidance on the use of configuration management within an organization.

- ISO 19011 – Guidelines for Auditing Management Systems. This document provides guidance on auditing management systems.

Core Tools for Corrective Action

Learn more about AS9110 Core Tools and how they are used

- ARP9013-1A – Statistical Product Acceptance Requirements Using Isolated Lot Sampling Methods

- ARP9013-2A – Statistical Product Acceptance Requirements Using Attribute Or Variable Lot Acceptance Sampling Plans

- ARP9013-3A – Statistical Product Acceptance Requirements Using Process Control Methods

- ARP9013-4A – Statistical Product Acceptance Requirements Using Continuous Sampling, Skip-Lot Sampling, Or Methods for Special Cases

- AS9145 – Requirements for Advanced Product Quality Planning and Production Part Approval Process

- ARP5580 – Recommended Failure Modes and Effects Analysis (FMEA) Practices

- ARP9136 – Root Cause Analysis and Problem Solving

Complete list of Standards referenced in AS9110

These standards are available to purchase here.

SAE Standards referenced in AS9100D

These standards are available to purchase here.

Aerospace Software

Aerospace Supply Chain

-

- ARP9114B – Direct Ship Guidance for Aerospace Companies

- ARP9134A – Supply Chain Risk Management Guidelines

- ARP9162 – Aerospace Operator Self-Verification Programs